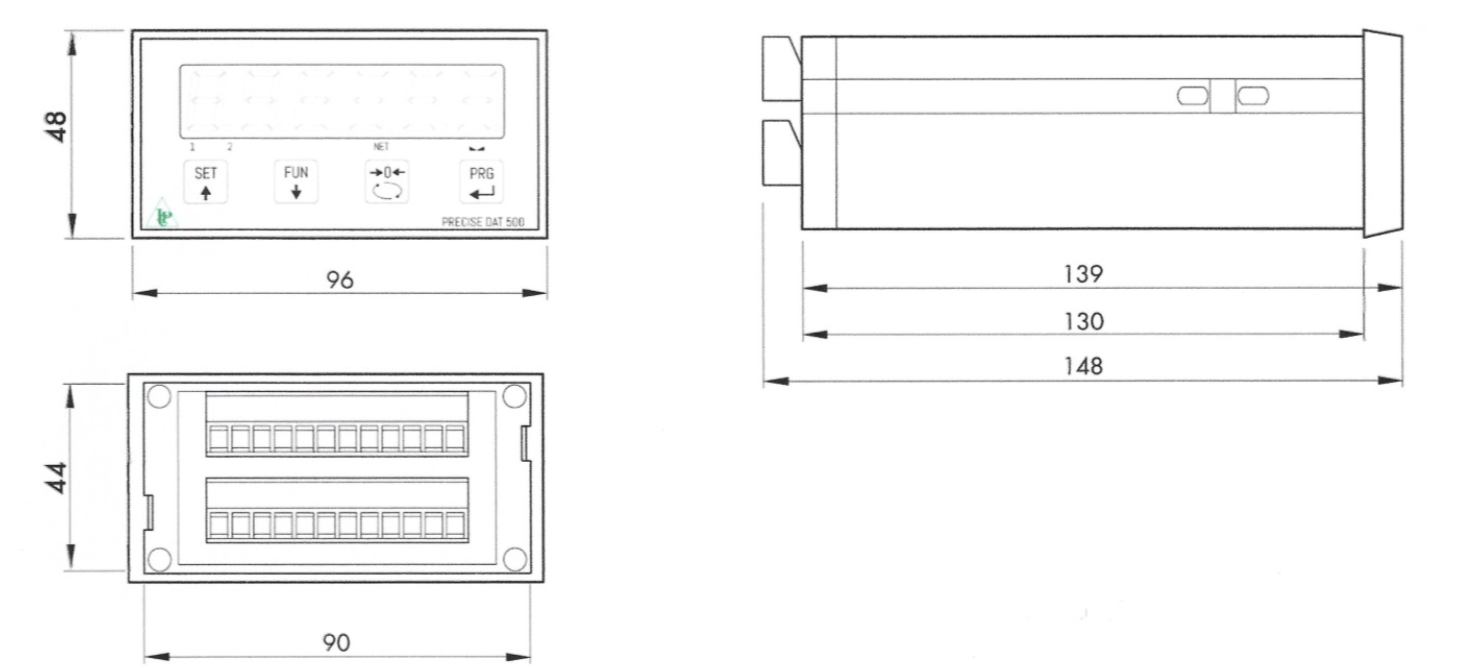

EP500 Panel Mount

Weight Indicator

- A highly cost-effective weighing instrument for process vessel weighing and platform scales

- 6 digit red LED 14mm high 7 segment display

- 50 conversions per second for quick update in dosing applications

- Ten-point linearisation compensation

- Optional 16-bit 4-20 mA analogue output

- Calibration and set-up via front panel or by PC with “innovation” software

- High precision 24 bit analogue to digital conversion with 60,000 count resolution

- RS232, 422 or 485 serial port with ASCII or ModBus RTU

- Two setpoint outputs (opto isolated)

- Optional Fieldbus connectivity with Profibus-DP, DeviceNet, TCP/IP and more

The Type EP500 delivers excellent weighing performance plus a host of useful communication features. This combination makes it the perfect choice for hopper and vessel weighing applications where connectivity to PLCs and other types of control system is required.

The fast 50 conversions per second ADC make it ideal for batching and dosing applications. Filtering can be adjusted to suppress signal fluctuations due to mechanical vibration etc.

Connectivity

The Type EP500 is equipped with a serial port that can be used for RS232, 422 or 485 communications. This port can be connected to a printer to record weight data, a remote display or a PLC/Computer Control System. Data flow is bi-directional and setpoint values can be written to the indicator from the PLC or computer.

The protocols it supports makes for easy interfacing to most PLCs etc. Internal option cards (replacing the 4-20 mA option) allow connection to Profibus -DP or DeviceNetä networks. Profibus, DeviceNetä, TCP/IP and other popular protocols are all available via an optional Fieldbus gateway.

Digital inputs and outputs

Two setpoints are provided. These are solid-state switches with a maximum load of 100 mA at 24 Vdc. The hysteresis setting is menu selectable. The digital inputs can be used for Tare, Zero and Print commands.

Calibration and setting up

The Type EP500 has an easily learnt menu-driven set-up procedure using the keys on the front of the instrument. Alternatively, the instrument can be set up using a PC and a Windows based software package. One benefit of the PC approach is the availability of a ‘data sheet’ calibration mode. This allows the unit to be calibrated according to the mV/V performance of the load cell selected and avoids the need for dead weights or other calibration references.